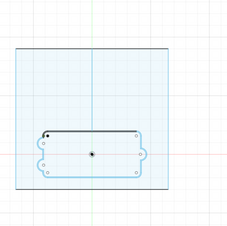

The first step in building my bass was creating a design. I used Fusion 360, a 3d modeling program to draft the overall shape. Through this process, I was never pleased with the design. Fusion is extremely sensitive to how curves interact with one another, which was limiting how I could manipulate the profile. After many minor revisions, I produced the first version and printed it on a roll of paper. Unfortunately, as soon as I could see the shape physically, it became apparent that it was not thick enough, and my neck measurements were incorrect. After trying to correct the drawing for hours, I eventually gave up and started a completely new one. Starting fresh allowed me to quickly iterate upon my previous design and produce a second version of the profile with significantly better scaling and cosmetic attention. I then modeled the 3d aspect necessary to have in my plan before I started cutting wood. The next step was designing templates for the different holes, which would need to be routed into the body of my bass guitar for various parts such as knobs, pickups, and batteries. Finally, I compiled all of the information into a master plan document and was ready to work in the real world.